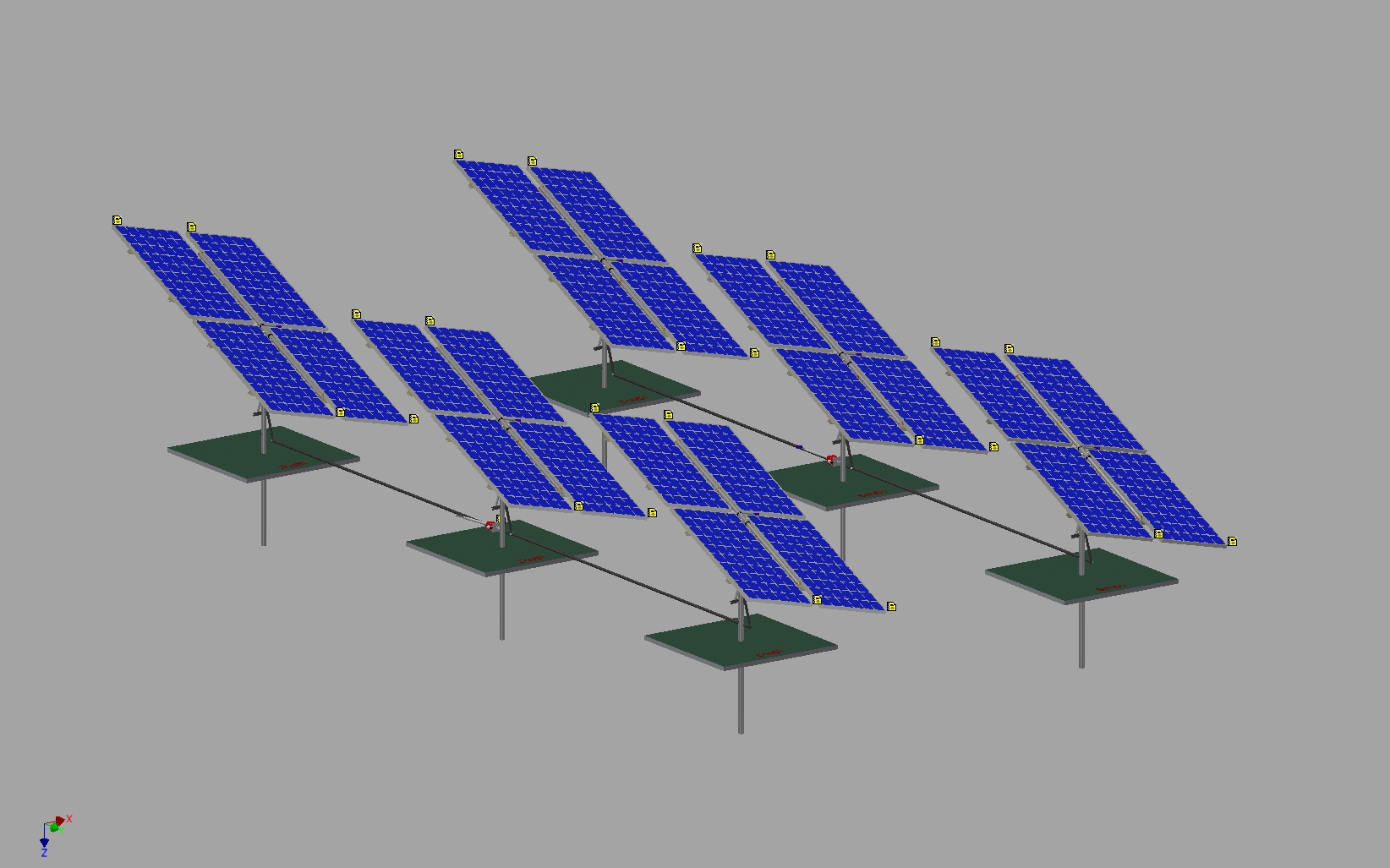

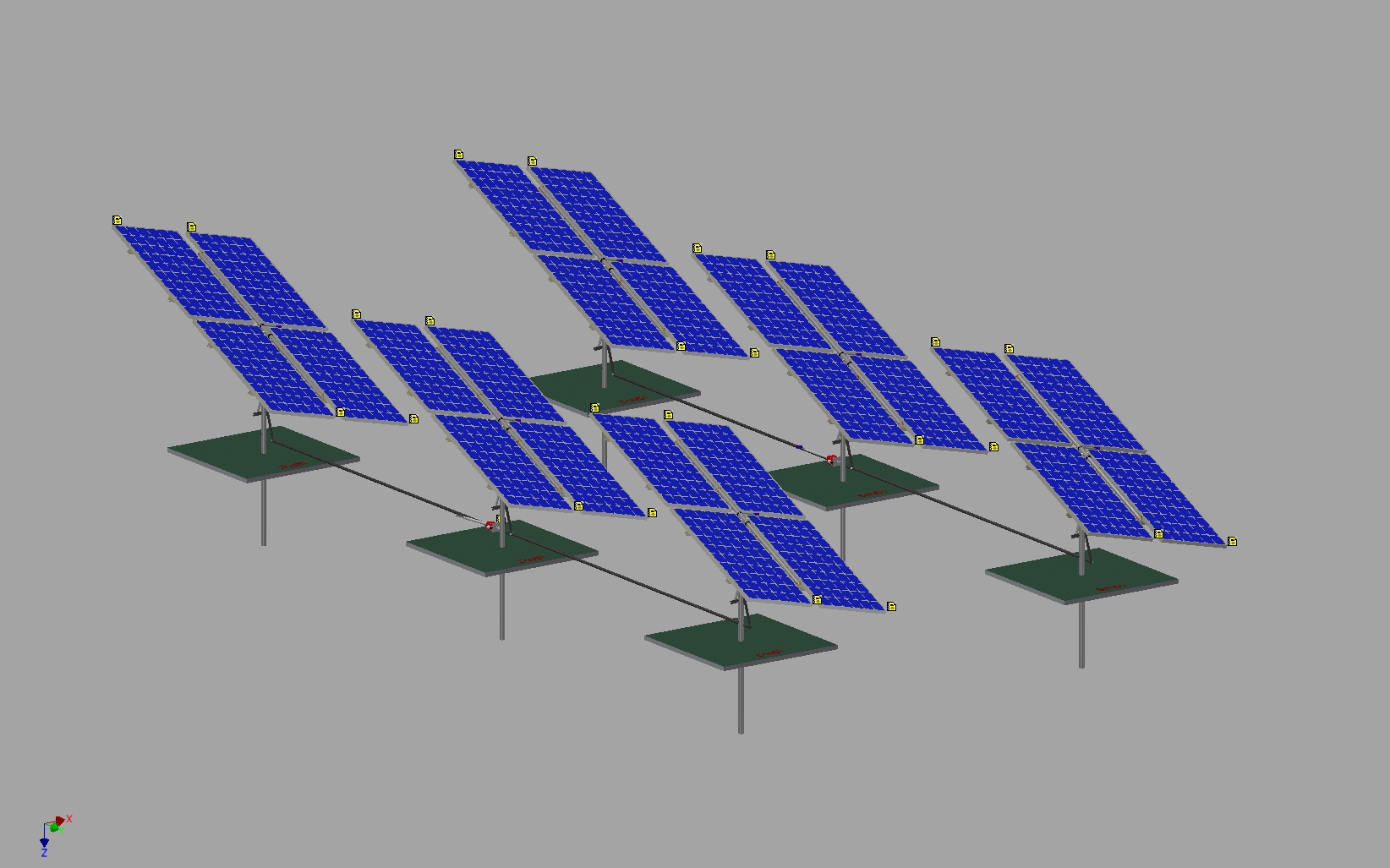

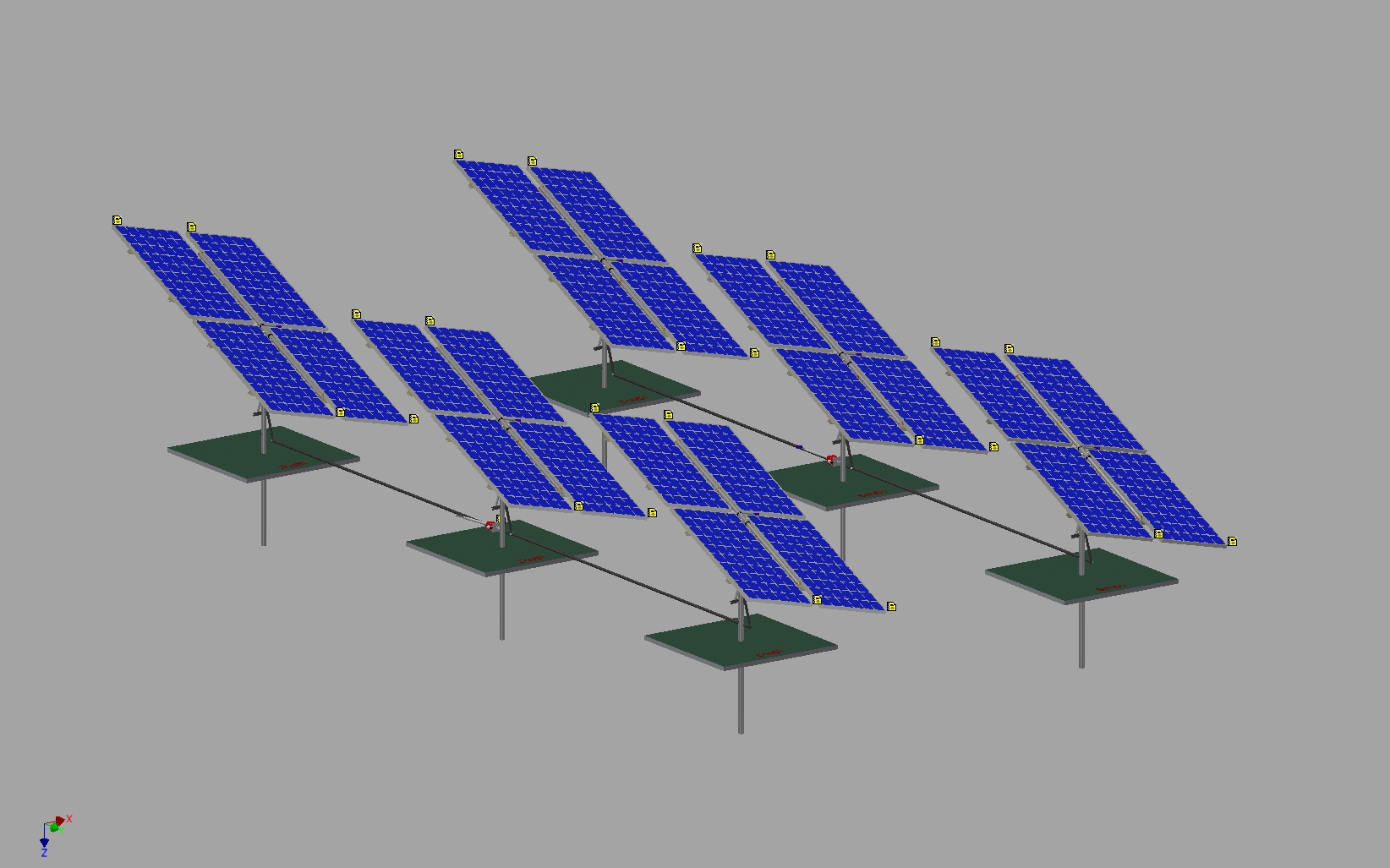

Link to the solar farm in San Antonio, Texas. It consists of 480 trackers of the azimuth - elevation type. I assume each array is 10 kWatts, so the farm is 4.8 mega watts. These arrays are large and require larege construction equipment and lots of concrete to anchor the towers. In the same physical area, one could place 3,840 each of a 1250 watt tracker. That is about 8 each of the 1250 watt trackers to equal a 10 kWatt tracker. It seems highly likely to me that the fabrication and installation cost of 8 small trackers is hughly less expensive than one single 10,000 watt tracker. Land areas, to avoid one tracker from shadowing another would be the same. Note one drive motor driving 3 arrays.

Engineering: Why such a small motor? 8 Watts? The actuator speed is very slow - and intermittant. On for a couple of seconds, off for a couple of minutes. In addition to which screw jacks are efficient at making forces. The load, is to move some linkages to pivot the panels. The spar, upon which the panels are mounted, is supported by ball bearings. So, except for a wind induced load, the force to rotate the panels is very little.